Vibsorb Etched PTFE Canada

Benchmark stocks Vibsorb single side etched ptfe in a wide variety of thickness's including both filled and unfilled variations.

Vibsorb PTFE / Teflon with single side acid etching is ideal for bonding to the Vibsorb vibration pads, steel or other surfaces using our high quality 2 part epoxy systems.

Benchmark can cut to size , drill holes as per your specification .

What is Etched PTFE?

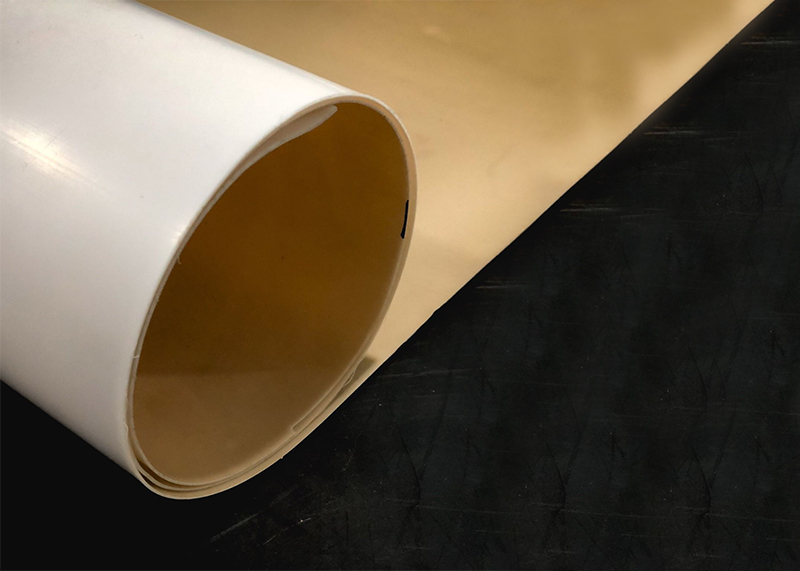

Etched PTFE is a highly specialized form of polytetrafluoroethylene (PTFE). It is made by etching the surface of the PTFE to create a uniform and controlled pattern. This process creates a roughened surface to which other materials, such as metals, can be bonded.

The etching process is carried out using either an acid or a laser. The acid etching process is the most commonly used and it involves submerging the PTFE in a bath of acid and allowing it to react with the surface of the PTFE. Laser etching is a more precise method, involving a laser beam to etch the surface of the PTFE.

Etched PTFE (Polytetrafluoroethylene) is a polymer material manufactured to produce sheets and tubes of various sizes, thicknesses, and shapes. It is a high-performance material that is extremely durable and resistant to wear and tear. It has countless applications across many markets, including automotive, aerospace, medical, and construction.

The benefits of etched PTFE can be seen in its superior mechanical properties, high chemical resistance, and excellent thermal stability. In this blog, we’ll discuss the various benefits of etched PTFE, its types and applications, how it is made, and its advantages and disadvantages.

Key Etched PTFE Terms:

- Alkali metals

A group of elements consisting of lithium (Li), sodium (Na), potassium (K), rubidium (Rb), cesium (Cs), and francium (Fr). Molten alkali metals are one of the few substances that react with PTFE. The chemical reaction between PTFE and alkali metals defluorinates the PTFE. - Angstrom

Unit of measure equivalent to one ten millionth of a millimeter. - Coefficient of friction

A dimensionless number representing the lubricity of a material. A lower coefficient of friction means that a material is more slippery. Usually measured against polished steel. - Defluorination

The removal of fluorine from a substance. In the etching process, defluorination specifically refers to fluorine atoms being removed from PTFE molecules, which leaves a surface composed mostly of electron-deficient carbon atoms. - Lubricity

The slipperiness of a material. Materials with higher lubricity are more slippery than others. In the plastics industry, this specifically refers to the material's coefficient of friction.

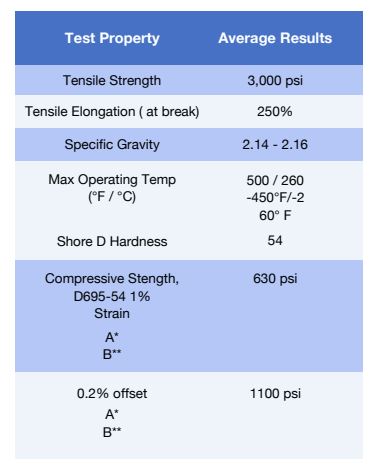

Typical Physical Properties of Etched PTFE:

Virgin PTFE is almost universally inert. Components made of this material exhibit excellent impermeability to most corrosive liquids, vapors, and gases, even at elevated temperatures, as well as under pressure and vacuum. Virgin PTFE is affected only by molten alkali metals, fluorine and chlorine tri-fluoride at elevated temperatures and pressure.

Virgin PTFE has exceptional electrical and dielectric properties but can be somewhat limited for mechanical applications. It will creep or cold flow when a compressive load is applied. Since PTFE is a soft material, it can also experience a high rate of wear when used in a dynamic situation. The addition of inert fillers will increase resistance to wear, deformation and creep.

A* designates properties tested parallel to direction of molding.

B** designates properties tested perpendicular to molding direction.

PTFE is a critical material used in countless applications across a number of industries. Its unique physical, chemical, and dielectric properties make it ideal for use in chemical processing equipment, aerospace electronics, semiconductor processing, medical and pharmaceutical equipment, and other applications. However, the lubricity of PTFE makes it difficult to bond, either to itself or another surface.

Despite this challenge, most industrial grade adhesives will readily adhere to PTFE after the material has been chemically etched. Chemical etching fundamentally alters the surface of the material to permit adhesion without sacrificing PTFE's most valued characteristics.

Benefits of Etched PTFE:

Etched PTFE has a variety of benefits, making it a highly sought-after material for many industries.

- Chemical Resistance: Etched PTFE has excellent chemical resistance, making it ideal for use in chemical processing plants and other harsh environments.

- Thermal Stability: Etched PTFE is able to withstand high temperatures, making it suitable for applications such as heat exchangers and nuclear reactors.

- Low Coefficient of Friction: The etched surface of PTFE has a low coefficient of friction, making it ideal for use in bearings and other machinery.

- Non-Stick: The low friction of etched PTFE makes it ideal for use in non-stick coatings.

- High Strength and Durability: Etched PTFE is extremely strong and durable, making it suitable for use in high-stress applications.

- Low Cost: Etched PTFE is a cost-effective material, making it a popular choice for many applications.